Your design can come from three sources:

Website Design: Choose a design from our website gallery and we will customize it to your needs.

Design Your Own: Choose & customize a design from our design your own range.

Custom Design Brief: Create a brief for our in-house designers to follow.

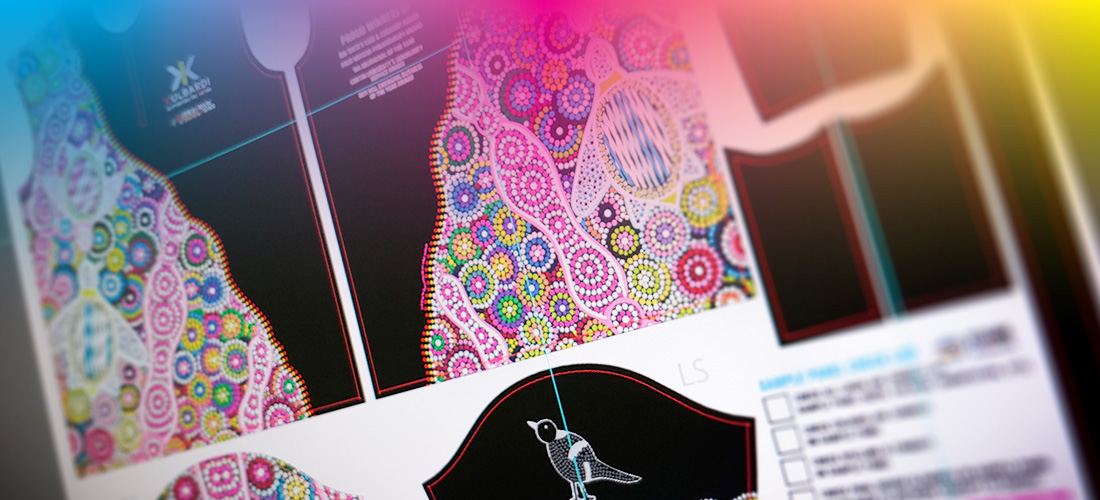

After the concept is ready, your account manager will send it to you for final approval or changes if required. If you have concerns about colours, positioning, or logo sizes, we can create a flat sample panel for you to review before final printing and production.

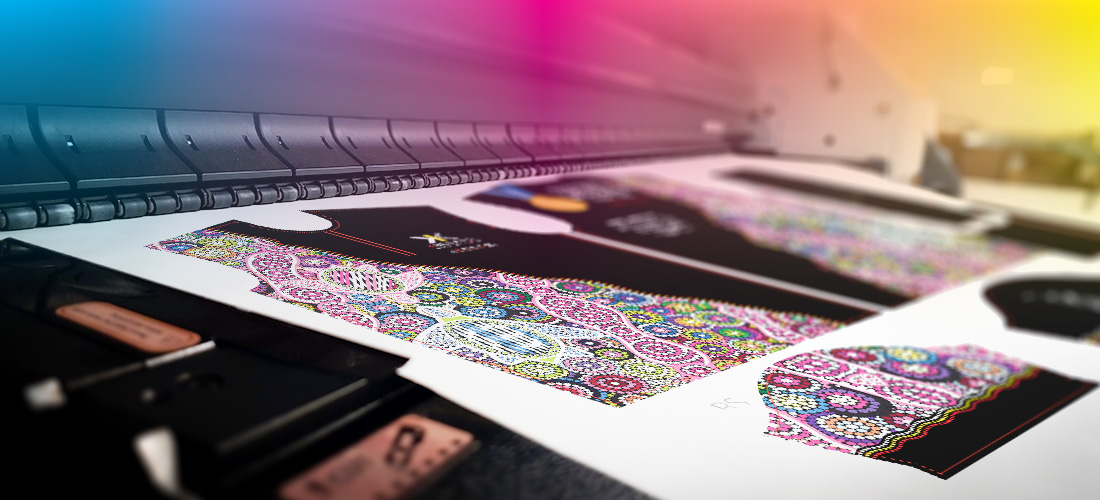

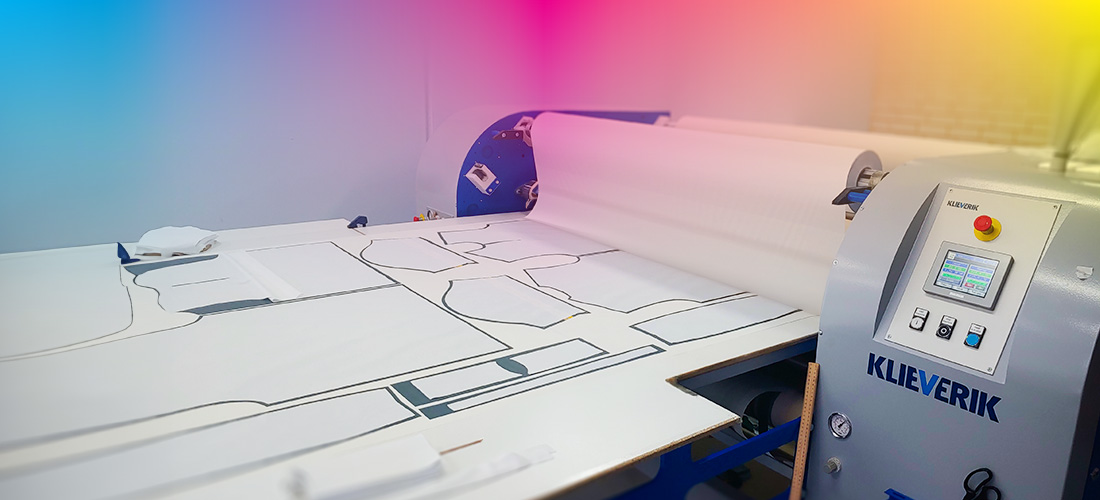

Once your final approval & order is ready to go, we’ll prepare the print files required for production.

Download our ARTWORK GUIDE